Per the E3D instructions, heat the hotend to 285. You should see a room temperature reading from the hotend thermistor. I did not run the extruder cable inside the wire sock.Ģ0. Make sure you attach the 4 colors to same 4 black/white wires in the original cable in the same order. You will need to clip the white connector of the black/white wires and then clip the flat connector off the Hemera cable. Test showed that coils of both steppers are aligned in the same pin out. There is a lot of back and forth about the wiring of the Hemera and the Creality 40-42 stepper that they use for their extruder. For tidiness, if you want, run the cables inside the wire sock that originally came with the printer.ġ9. I cut the connector off the fan and soldered Yellow to Red and Black to Blue.ġ8.

E3D HEMERA ENDER 5 PLUS

I selected the 5015 fan which had a short black and red wire plus a connector. Take the blue and yellow wire from the original part cooling fan and connect them to the wires of your new part cooling fan. Here you should match red to red and black to black.ġ7. Take the black and red wire from the hotend cooling fan and solder it to the black and red wire from the original hotend cooling fan. Make sure to connect the thermistor to the extension cable.ġ6. Again, it does not matter which wire goes to which, as the thermistor is a variable resistor that changes resistance as the temperature changes. Take the black and red wire coming from the thermistor extension cable and solder it to the two white wires from the original thermistor. It does not matter which wires you solder together, as this is just a big resister that gets hot.ġ5. Take the two yellow wires from the heater and solder them to the two red wires from the original heater. This protects your joints from shorting out. On these connections you are going to want to use some type of heat shrink tubing. The Blue/Yellow should be paid extra attention, depending on your part cooling fan. You can always tidy up wire, but you can’t really make it longer without extra solder joints. Make sure that you leave extra length from the connector to where you cut. You will need to cut the original wires off from the original hotend. I have years of electrical engineering training and are good with a soldering iron. If so, look to get different connectors to connect the wires together. If you are not comfortable with soldering, the next steps might not be for you.

Disconnect the 4 connections for the hotend (Heater, Thermistor, Cooling Fan, Part Cooling Fan) where they connect to the cables coming out of the control block at the base.ġ3. Reset the tensioner so that the belt is tight.ġ2. Reconnect the belt on the left side of the carriage.

When you are done, the Hemera should be hanging on the carriage and move freely back and forth.ġ1.

E3D HEMERA ENDER 5 HOW TO

They're a lot of videos on how to do this for Creality printers. Set the tension of the rollers using the eccentric nut. Place the Hemera mount and Hemera onto the carriage plate and reassemble the rollers.ġ0. You need to do this as the Hemera mount makes getting that belt connected almost impossible.ĩ. Connect the right-hand side of the carriage back to the belt. I will not give specific screw lengths as you need to make sure as I just said that you use the correct length and don’t bust off the stepper motor tabs.Ĩ. I used M3 pan head screws but had to adjust my length due to poor print quality of my mount because of my hotend issues. Pay attention that you are using the correct length so that you don’t overstress the tabs and break them off.

Now insert M3 screws through the 3D printed Hemera mount into the nuts in the stepper motor tabs. Use some blue painters’ tape to tape them in place so they don’t fall out.ħ. Insert the two roller bolts into the Hemera mount. Remove the top two guide wheels, which should allow you to take the carriage off the rail.Ħ. Remove the belts from each end of the hotend carriage. Loosen the tensioner on the left side of the printer rail. Assemble the Hemera per the E3D Instructions.ĥ. I keep boxes of different sizes on hand.Ģ.

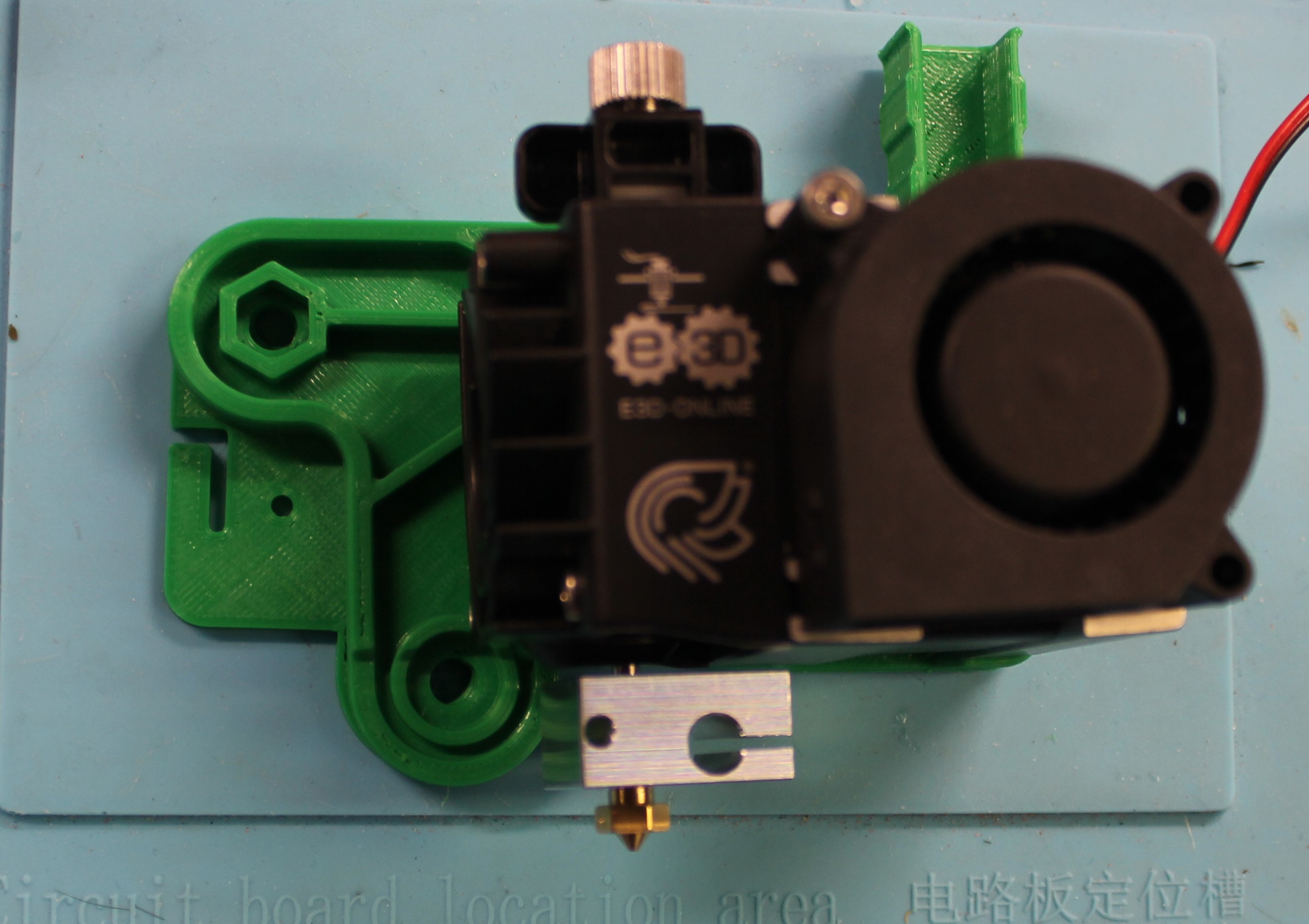

Fixed Torque Handle ( ) I printed the 3Nm handle to set the torque of the nozzle per E3D instructions. Front Bar Relocator ( ) I found this useful to drop the front bar and make more room for the print head. Filament Guide ( ) I modeled this to bring the filament to the top of the printer and let it be pulled in by the Hemera.į. Filament Guide ( ) I have an enclosure from 3D Upfitters and need to turn the filament direction.Į. I'm now using this fan duct with much better performance. 5015 Fans ( ) I’m not sure I’m happy with this fan. Hemera Cooling Duct ( ) This might not be the best cooling duct, but it’s what I have started with.Ĭ. Hemera mount ( ) This works for both BL Touch and EZABL. Print all the 3D parts before you do anything to your printer.Ī.

E3D HEMERA ENDER 5 SERIES

So here are a series of steps that I took:įirst you will need a series of parts.

0 kommentar(er)

0 kommentar(er)